Sortieren + Filtern

Hochtemperatur-Anti-Seize-Schmiermittel

Gewindeverbindungen für Hochtemperaturanwendungen werden meist aus hochlegierten Stählen hergestellt. Aufgrund der Edelmetalle dieser Legierungen gibt es auf ihnen kaum Oxidschichten, die sie vor dem Festfressen schützen könnten.

Eine Schmierung ist unbedingt erforderlich, um ein Festfressen der Verbindungen und andere Verbindungsfehler wie Spannungsrisskorrosion durch im Schmiermittel enthaltene Elemente zu vermeiden. Für diese Anwendungen ist es sehr wichtig, dass Schmiermittel mit dem richtigen Reinheitsgrad ausgewählt werden, um eine Beschädigung der Legierungen und ein Festfressen der Verbindung bei hohen Temperaturen zu vermeiden.

Wie wählt man Hochtemperaturfett aus?

Berücksichtigen Sie bei der Auswahl eines Hochtemperaturfetts die folgenden Faktoren:

- Bestimmen Sie den tatsächlichen Temperaturbereich. Die Betriebstemperatur kann niedriger sein als erwartet. Verwenden Sie einen Kontakt- oder berührungslosen Sensor, um die Betriebstemperatur des Schmiermittels zu messen. Übersteigt die Temperatur 392ºF (200 °C)?

- Ist es intermittierend oder kontinuierlich? Wenn das Problem dauerhaft auftritt, suchen Sie nach einem Spitzenprodukt, das Ihren Betriebsanforderungen entspricht.

- Sind Betriebs- und Stillstandszeiten der Maschinen mit Heiz- und Kühlzyklen verbunden? Überlegen Sie, ob Feuchtigkeit durch die Atmosphäre oder durch die Dampfeinspritzung der Maschine entstehen kann

- Was ist ein sinnvolles Schmierstoffwechselintervall bzw. eine Nachschmiermöglichkeit? Wenn die Nachschmierung schwierig sein sollte, sollten Sie ein Spitzenprodukt in Betracht ziehen, um die Betriebskosten zu senken, auch wenn es teurer ist.

- Berücksichtigen Sie alle kosmetischen Probleme. Kann das Produkt während des Vorgangs auf das Element tropfen? Die Häufigkeit und Menge der Nachschmierung müssen je nach Produktverunreinigungsproblematik abgestimmt werden.

Arten von Hochtemperaturfetten :

- Hochtemperaturfett aus Molybdän und Graphit : Wird in Lagern, Trolleyrädern, Lüftern, Filmspannketten usw. verwendet.

- Hochtemperatur-Silikonfett : Beständig gegenüber äußeren Einflüssen.

- Kupferfett : Wird häufig in Bremssystemen und industriellen Maschinenkomponenten verwendet.

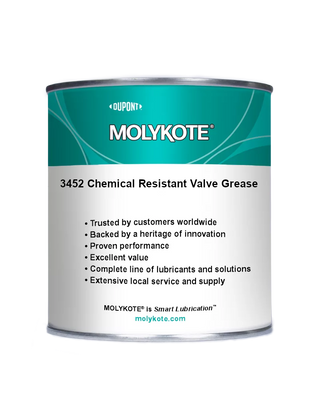

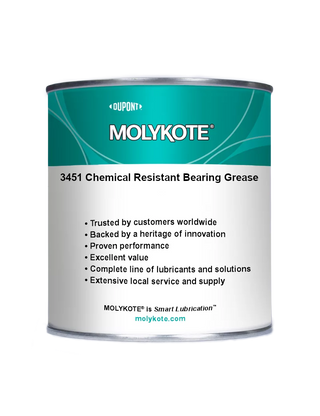

- Produkte auf Ölbasis von Perfluorpolyether (PFPE) : Wird in der chemischen Industrie sowie in Kraftstoff- und Chemikalientanks verwendet

Durch die Auswahl der richtigen Hochtemperaturschmierstoffe für bestimmte Anwendungen können Unternehmen die Leistung ihrer Geräte verbessern, die Wartungskosten senken und die Gesamtproduktivität steigern. Mit speziell entwickelten Hochtemperaturschmierstoffen können diese Probleme gelöst werden.

Viele der in Hochtemperaturfetten verwendeten modernen Öle (fluorierte Polyether, Perfluorpolyether, Phenylpolyether, Silikone usw.) überdauern ihre Verdickungssysteme.

Hochtemperaturfettanwendungen:

- Walzwerklager

- Brech- und Siebmaschinen

- Wälzlager für Klebe-, Papierverarbeitungs- und Trocknungsmaschinen

- Ofenroste und Feuerrollen für Backöfen

- Ofenlüfterlager

- Heißasphaltmischanlagen

- Förderbänder, industrielle Lackierstraßen

- Raumfahrtausrüstung (300 Grad Hochtemperaturfett wird bevorzugt)

- Wasserpumpen und Elektromotoren