Sort + Filter

Lubricants for the pharmaceutical and medical industries

Lubricant Solutions

Lubricants can be mineral or synthetic based. Unfortunately, many of them do not provide both the support needed to keep systems running and the safety in some medical applications. However, MOLYKOTE® high-performance lubricants are specifically designed to reduce friction and wear, extend relubrication intervals and reduce maintenance costs. This is especially important where performance is required beyond the capabilities of conventional greases and oils. Other types of greases and oils may not provide reliable and lasting benefits.

DuPont lubricant formulation process is the result of combining innovative technology and high quality standards to ensure visible results from the first application. DuPont industrial lubricants also provide long-term production solutions for industries with high regulatory standards and demanding operating conditions. These superior sliding solutions are compatible with most medical materials, making them ideal high-purity solutions.

DuPont lubricant formulation process is the result of combining innovative technology and high quality standards to ensure visible results from the first application. DuPont industrial lubricants also provide long-term production solutions for industries with high regulatory standards and demanding operating conditions. These superior sliding solutions are compatible with most medical materials, making them ideal high-purity solutions.

Lubrication of production equipment

- Solid, liquid and soft oral gels

MOLYKOTE® Lubricants by DuPont

MOLYKOTE® lubricants are the optimal solution for a wide range of applications in the medical and pharmaceutical industries. Processes with chains and moving parts on the production line require lubrication, but the recommended types are not always classified for use in the food and pharmaceutical industries. Fortunately, the DuPont line of pharmaceutical lubricants can help reduce friction and prevent corrosion, extending the life of the system. Below is a list of the types of applications that can benefit from a suitable and reliable lubricant coating.

| Preparation tanks | Vacuum pumps | Samples | Train dryers |

| Inspection pumps and clamps | Blister machines | Review teams | Tabletting machines |

| Plates | Sealants | Fillers | Containers |

Below are popular lubricants for the medical and pharmaceutical industries:

|

LUBRICANTS

|

Type of grease

|

NLGI (Grease Consistency)

|

VISCOSITY

@40°C cSt |

LUBRICANTS

CONSTANTLY |

SERVICE TEMPERATURE

°C |

|---|---|---|---|---|---|

|

Molykote® G-0052FM |

MO and AL compound thickener

|

2

|

98.7

|

White solids

|

From -17 to 150

|

| Molykote® G-4501FM |

Thickener complex PAO and AL

|

1

|

100

|

PFTE,

white solids |

From -40 to 150

|

|

Molykote® G-1502FM |

Thickener complex PAO and AL

|

2.5

|

220

|

White solids

|

From -40 to 149

|

DuPont MOLYKOTE® Anti-Seize Pastes

Most pharmaceutical manufacturing and pharmaceutical applications also benefit from DuPont MOLYKOTE® paste. This specialist compound is ideal for the most common types of pharmaceutical systems, including:| Preparation tanks | Vacuum pumps | Samples | Train dryers |

| Inspection pumps and clamps | Blister packaging | Filming | Sets |

| High Temperature Requirements | Anti-corrosion requirements | Counters |

DuPont MOLYKOTE® dispersions

DuPont lubricant dispersion formulations also provide a range of performance enhancing solutions for most medical device and pharmaceutical applications. Below are some of the most common applications where these dispersions are effective.| Silicone greases | Release agents | Drums | Review teams |

| Sealants | Fillers | Preparation tanks | Vacuum pumps |

| Samples | Train dryers | Blister packaging | Counters |

|

DISPERSION

|

BASE OIL

|

ADDITION

|

VISCOSITY

@40°C cSt |

VISCOSITY INDEX

|

POWDERING POINT

°C |

|---|---|---|---|---|---|

|

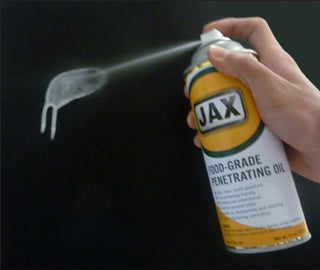

Molykote® FM Food Machinery OIL SPRAY |

MO

|

EP/AW

|

96

|

102

|

<-10

|

Lubricants for the medical and pharmaceutical industries

Pharmaceutical plants require reliable industrial maintenance using materials that meet critical industry regulations for the efficient formulation, production and handling of drugs and pharmaceuticals. Unplanned maintenance and system failures can be costly, but they can be easily avoided with high-quality DuPont lubricants. These lubricants are corrosion-resistant, resistant to water washout, provide high and low temperature stability and prevent friction damage.

Special DuPont technology provides intelligent lubrication that meets specific industry standards for the operation of pharmaceutical manufacturing equipment.

Special DuPont technology provides intelligent lubrication that meets specific industry standards for the operation of pharmaceutical manufacturing equipment.

Lubrication in production equipment

- Oral solids and liquids

MOLYKOTE® Oils by DuPont

The pharmaceutical and drug manufacturing industries can benefit greatly from the use of DuPont lubricants for antifriction lubrication, as well as in many other applications. Below are typical applications where MOLYKOTE® Oil lubricants can be useful.

| Hydraulic systems | Compressor systems | Chain drives | Gear |

| Drums | Pumps | Teams | Pumps and Inspection Tapes |

|

OILS

|

ISO CLASS

|

BASE OIL

|

ADDITION |

VISCOSITY@40°C cSt |

INDEX

|

POWDERING POINT

°C |

FLASH-POINT

°C |

|---|---|---|---|---|---|---|---|

| Molykote® L-1232FM |

32

|

PAO

|

R&O

|

30.2

|

138

|

-60

|

241

|

| Molykote® L-1246FM |

46

|

PAO

|

R&O

|

47

|

138

|

-42

|

246

|

| Molykote® L-1668FM |

68

|

MO/

PAO |

R&O

|

63.1

|

113

|

-18

|

229

|

| Molykote® L-0532FM |

32

|

MO

|

R&O/

AW |

31.2

|

103

|

-18

|

215

|

| Molykote® L-1468FM |

68

|

PAO

|

PPD

|

65.8

|

131

|

-54

|

271

|

Additives and base fluids in personal care products by DOW™

XIAMETER™ PMX-200 Silicone Fluid

Dimethicone silicone oil 100% active polydimethylsiloxane polymer Odorless Silicone Fluid commonly used as a base in personal care products provides:

- Soft to the touch and delicate skin hydration

- excellent spreading properties

- Leaves no residue or deposits

- Non-greasy to the touch

- antiperspirants,

- deodorants,

- hairsprays,

- cleaning agents

- creams,

- skin creams,

- balms,

- bath oils,

- tanning products,

- nail polishes

| Benefits of using PMX-200 10 cSts | |

| Peeling off | TRUE |

| hair shine |

TRUE |

| wet and dry combing | True |

| Improved spread | TRUE |

| It increases | Slip, |

| Non-occlusive | TRUE |

| Performance benefits | sensory amplifier (touch smoothness) |

| Reduction | greasiness, stickiness |

| pH Effectiveness Range | 3-10 |

| Soft Feel Conditioner - Dry | TRUE |

| Used | Exterior Finish Protector, Exterior Wax, Conditioner & Sealer, Interior Restorer, Leather Care, Tire Care, Vinyl Protector |

| Wet combing | TRUE |

(4)