DOWSIL™ 796 Neutral Silicone

Silicone for circumferential sealing of window joinery, glazing of windows and doors

One-component, low-modulus, neutral-curing silicone sealant for PVC aluminum profiles and wood

Application:

Dowsil 796 silicone has been specially developed for sealing PVC, wood, glass, glazed surfaces and masonry

- perimeter sealing of windows and doors,

- windows glazing

- sealing PVC and masonry

Features and Benefits:

- Good adhesion without priming to various substrates

- low module,

- high flexibility

- 100% silicone sealant

- Neutral cure with TI titanium catalyst

- odorless

- Compliant with ISO 11600-F&G-25LM

- Resistant to ozone, ultraviolet radiation and extreme temperatures

Benefits of the application

| Application temperature range | 5 to 40°C |

| drying time | 35 minutes |

| Ability to move | 0.25 |

| Adhesion without primer | No primer |

| Resistance type | Ozone resistance, heat resistance, UV resistance |

Technical parameters of Dowsil 796

| Adhesion to | Aluminum, brick, glass, vinyl/PVC-U, wood |

| Appearance | Opaque |

| Chemistry | Neutral |

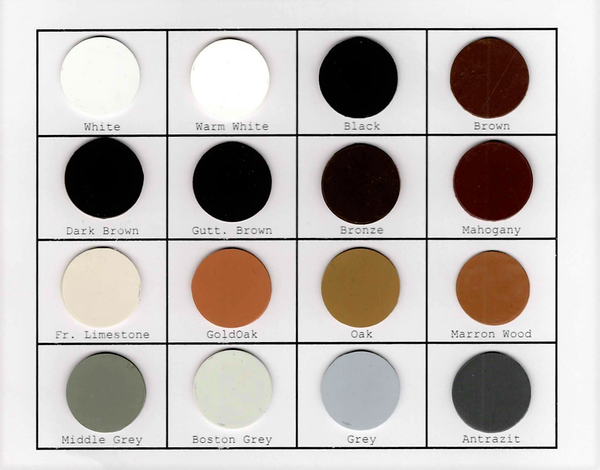

| Color | Anthracite, Black, Bronze, Bronze, Cream, Custom, Dark Brown, Dusty Grey, Golden Oak, Green (Catalyst), Grey, Oak, Pine, White |

| Hardness - Shore A | thirty |

| Low odor | TRUE |

| Movement | Mediocre |

| skin formation time (CTM 98B) | 15 minutes (at (23°C and 50% RH) |

| drying time (CTM 95A) | 35 minutes (at (23°C and 50% RH) |

|

curing speed 23°C and 50% RH (CTM 663A) |

1 day - 2mm 3 days - 3.5mm |

| Tensile strength | 1.8MPa (for 2mm thickness) |

| Elongation at break | 700% (for 2mm thickness) |

| Shelf life | 360 days |

| Specific gravity at 25°C | 1.52 |

| subsoil | Non-porous, porous |

Packaging and colors

Cartridge: 310 ml Sausage: 600 ml,

Color: white, black, grey, anthracite, brown, pine, oak, mahogany

Durability and Storage

When stored below 30°C (86°F) in the original unopened containers, DOWSIL™ 796 Silicone has a shelf life of 12 months from the date of manufacture.

THE DECLARATION OF PERFORMANCE

Intended use or uses of the construction product, in accordance with the applicable harmonized technical specification, as foreseen by the manufacturer:

- Facade sealant: EN-15651-1: F-EXT-INT-CC

- Glazing sealant: EN-15651-2: G-CC

System or systems of assessment and verification of constancy of performance of the construction product set out in Annex V:

- System 3: System 3 for reaction to fire

|

Essential characteristics |

Declared performance characteristics | technical standard |

| Reaction to fire | E-class | UNE-EN-ISO 11925-2:2011 |

| Emission of hazardous chemicals | Lack | See material safety data sheet |

| Waterproof and air permeability: | ||

| Sag resistance (ISO 7390) | ≤ 3mm | EN 15651-1.2 |

| Volume shrinkage (ISO 10563) | ≤ 10% | EN 15651-1.2 |

| Adhesive/cohesive properties at constant elongation for sealants | ≤ 0.9MPa | EN 15651-1.2 |

| non-structural used in cold climates (-30°C) acc | ||

| the revised ISO 8339 standard | ||

| Adhesive/cohesive properties at constant elongation for sealants | Lack | EN 15651-1.2 |

| non-structural used in cold climates (-30°C) acc | damage | |

| the revised ISO 8340 standard | ||

| Adhesive/cohesive properties after exposure to heat, water and artificial light according to ISO 11431 | Lack | EN 15651-2 |

| damage | ||

| Recovery (ISO 7389) | ≥70% | EN 15651-2 |

| Durability | Fulfills | EN 15651-1.2 |

How to use

When designing joints using DOWSIL™ 796 neutral silicone, the minimum joint width should be 6mm. For joints between 6 and 12 mm wide, a sealing depth of 6 mm is required. For joints wider than 12 mm, a width to depth ratio of 2:1 should be used.

Substrate preparation

Make sure that the surfaces to be sealed are clean, dry, sound and free from dust. Clean all joints of release agents, water repellents, cement laitance, dirt, old sealants and other contaminants.

Non-porous surfaces should be cleaned and degreased with a suitable solvent such as DOWSIL™ R-40 Universal Cleaner.

Porous substrates should be cleaned mechanically using a steel brush, grinding wheel or similar means.

Masking / Protection

Areas adjacent to joints should be masked with tape to prevent contamination of the substrate and ensure a clean line of sealant. The masking tape must be removed immediately after applying the silicone.

Priming

For PVC-U and most common construction substrates, no primer is required. However, it is always recommended to test before use.

Machining / Finishing

The joint should be machined within 5 minutes of application to ensure good contact between the sealant and the substrate.

Cleaning

Excess sealant can be removed in the uncured state using DOWSIL™ R-40 Universal Cleaner. If the sealant is incorrectly applied to porous substrates, it should be allowed to cure completely and then removed mechanically.

Limitations

DOWSIL™ 796 Neutral Silicone is not recommended for structural glazing. Do not use it on bituminous substrates, natural rubber, chloroprene or EPDM based substrates or on building materials that may bleed oils, plasticizers or solvents.

Special tests must be carried out on sensitive substrates .

DOWSIL™ 796 neutral silicone is not suitable for food contact.

It is recommended that DOWSIL™ 796 Neutral Silicone not be applied to surfaces that are

below 5°C (41°F).

This product is not tested or claimed to be suitable for medical or pharmaceutical use.

Product title

Vendor

€19,99 EUR | €24,99 EUR

Product title

Vendor

€19,99 EUR | €24,99 EUR

Product title

Vendor

€19,99 EUR | €24,99 EUR

Product title

Vendor